Whether you're a startup aiming to create a groundbreaking gizmo or a recognized business looking to improve your product line, comprehending the different types of PCB assembly services and producers is important. A one-stop-shop PCB assembly service enables services to enhance their production procedures by supplying end-to-end options that cover whatever from style to shipment.

One famous facet of PCB production is the increasing rate of interest in flexible PCBs. Flexible PCBs, or flex circuits, are made from thin, flexible products that permit for flexing, turning, and folding to suit one-of-a-kind shapes and designs. They are especially beneficial in compact devices where space is limited, such as mobile phones, wearables, and clinical devices. The capability to fit PCB styles right into unique areas while preserving performance is a game-changer in product style. Flexible PCB makers are outfitted with specialized modern technologies that make it possible for specific production procedures, making sure these boards carry out optimally under various problems. As sectors proceed to move towards smaller, a lot more versatile electronic devices, flexible PCBs are coming to be an essential component in item development, making it possible for developers to assume outside package in their developments.

Unlike flexible PCBs, rigid-flex PCBs provide an one-of-a-kind mix of both flexible and rigid components. These boards give the stamina and reliability of a traditional stiff PCB while permitting for the adaptability that developers need in specific locations. Rigid-flex PCBs are often used in applications where room is at a costs, such as in aerospace, automotive, and clinical tools. Their toughness, coupled with the capacity to incorporate multiple layers, makes them invaluable for high-performance applications. Picking a reputable rigid-flex PCB manufacturer makes certain that the boards are constructed to the highest possible requirements, which is important for performance-critical applications where failing is not a choice. The harmony of solid and flexible elements gives product developers adequate room to introduce while maintaining the needed resilience and capability.

PCB assembly is another vital element of the manufacturing process, bringing together all digital elements onto the PCB and ensuring they work as meant. With the quick advancements in technology, PCB assembly services are now able to integrate automatic procedures that boost efficiency and accuracy while lessening errors that can lead to pricey revisions.

Ceramic PCBs are another noteworthy advancement in PCB technology, known for their superior thermal conductivity, mechanical toughness, and electric insulation buildings. Suppliers specializing in ceramic PCB manufacturing utilize sophisticated methods and products to guarantee the optimal performance of these boards, highlighting the importance of partnering with specialists that comprehend the nuances of ceramic materials.

High-frequency PCBs stand for an additional important section of the market, specifically made to take care of regularities over 1 GHz. These boards are developed with distinct materials and techniques to decrease signal loss and crosstalk. Applications in telecoms, radar systems, and microwave gadgets rely greatly on high-frequency PCBs to make sure reputable performance. As the need for high-speed information transmission and effective communication systems proceeds to expand, the requirement for high-frequency PCB manufacturing becomes extra noticable. Producers of high-frequency PCBs require customized understanding and advanced testing capacities to ensure that the products utilized can carry out effectively under the stress of high-frequency applications. By concentrating on utilizing materials such as PTFE and various other low-loss dielectrics, together with meticulous manufacture procedures, these producers can produce PCBs that fulfill the rigid demands of modern-day digital applications.

The landscape of PCB design and production is differed, with each manufacturer providing various capacities, technologies, and competence degrees. As businesses look to distinguish themselves in an affordable marketplace, forming calculated collaborations with PCB assembly and manufacturing professionals is essential. A one-stop-shop PCB assembly service offers incorporated solutions that can adapt to a here company's specific demands, assisting in a smooth change from concept to production.

Quality assurance is one more considerable element that must never ever be forgotten throughout the PCB production and assembly procedures. Applying quality checks at various phases-- from raw product examination to last assembly examinations-- makes certain that possible flaws are recognized early in the procedure, decreasing the threat of failings in the area.

As services endeavor into the digital age, the implications of the Internet of Things (IoT), synthetic intelligence, and big data call for a durable strategy to PCB layout and production. The demand for interconnected tools is boosting, requiring intelligent PCB solutions A one-stop-shop PCB Assembly Services that not only sustain typical capabilities yet additionally incorporate sophisticated communication, processing, and noticing capabilities. Companies are continually looking for means to maximize their PCB creates to support these technological advancements while making certain effectiveness and cost-effectiveness. Partnering with ingenious PCB assembly provider permits firms to take benefit of the current patterns and technologies in the sector, making certain that they stay relevant and affordable in an ever-changing market landscape.

In final thought, the get more info world of PCB assembly and production is complex and large, incorporating different crucial aspects that add to the total success of electronic devices. From one-stop-shop PCB assembly services specializing in rigid-flex and flexible PCB manufacturing to the innovative production of ceramic and high-frequency PCBs, the importance of know-how and quality in this market can not be overstated. As modern technology continues to progress at a rapid rate, aligning with the appropriate manufacturing companion will certainly be crucial, making sure that companies can stay on top of market demands while supplying innovative, high-grade products. Whether you are seeking to establish your following groundbreaking digital device or looking for to improve existing items, recognizing the breadth of PCB services readily available is important for success. By leveraging these services and modern technologies, business can remain at the leading edge of the digital development wave, leading the method for future improvements in the sector.

Danny Pintauro Then & Now!

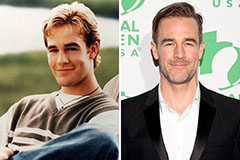

Danny Pintauro Then & Now! James Van Der Beek Then & Now!

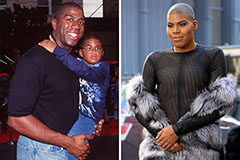

James Van Der Beek Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!